This plan greatly improves safety and convenience by replacing major parts in the machine room which serve as key elements for operation, including the control panel, traction machine, and hydraulic unit.

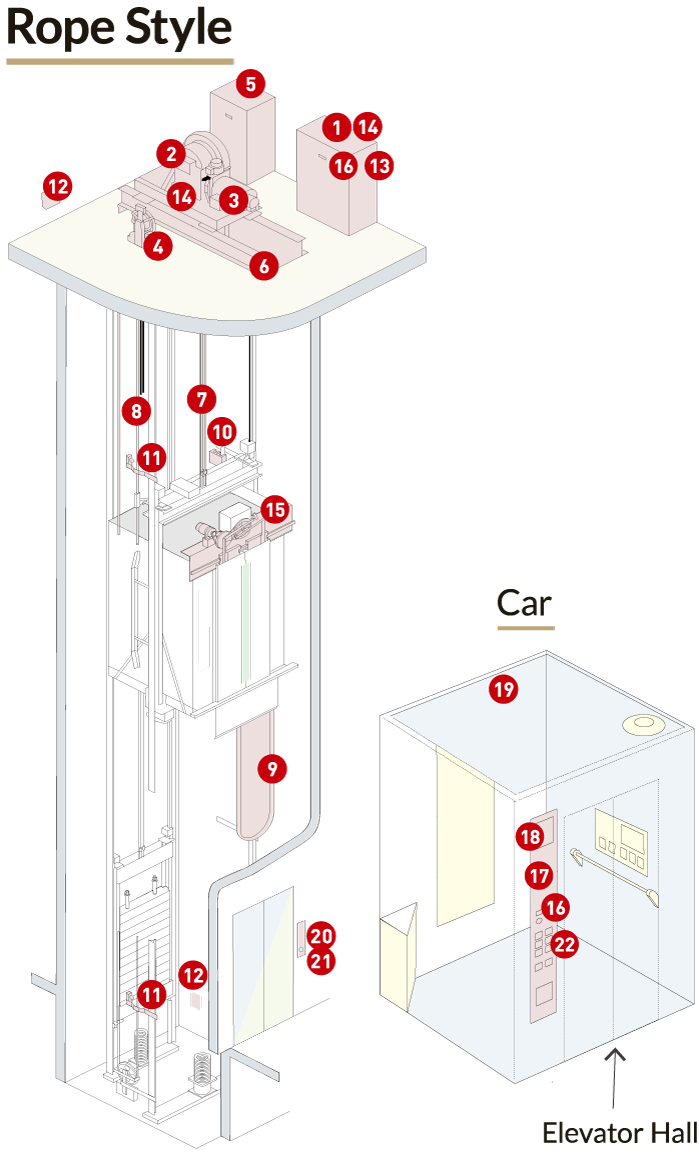

- Traction (Rope) Elevators

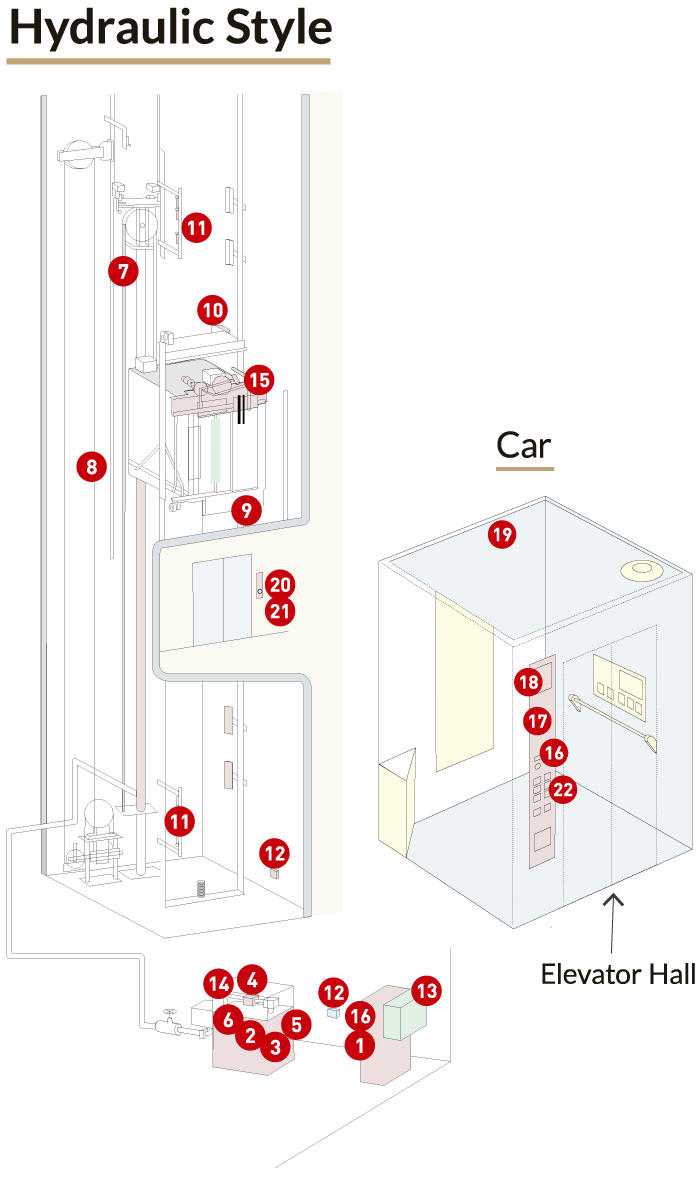

- Hydraulic Elevators

|

Machine/Equipment Name |

|

|

Machine room ① Control panel ② Traction hoist machine ③ Motor ④ Governor ⑤ Floor selector ⑥ Machine bed plate

Shaft ⑦ Main rope ⑧ Governor rope ➈ Compensation cables ⑩ Positioning system ⑪ Limit switch |

Basic Safety Equipment ⑫ Earthquake management equipment ⑬ Power outage automatic lowering system ⑭ Unintended car movement protection (UCMP)

Elevator Cab ⑮ Door controller ⑯ Intercom ⑰ Internal control panel ⑱ Internal display ⑲ LED car lighting switchover

Elevator Hall ⑳ Hall control panel ㉑ Hall display ㉒ Buttons |

|

Machine/Equipment Name |

|

|

Machine room ① Control panel

Shaft ⑦ Hoist rope |

Basic Safety Equipment ⑫ Earthquake management equipment ⑬ Power outage automatic lowering system

Elevator Cab ⑮ Door controller

Elevator Hall ⑳ Hall control panel |

01. Improved convenience & comfort

Major key components that are most essential to elevator operation require replacement as age increases the risk of failure or damage.

① Control panel (traction & hydraulic)

Updating the control panel to the latest system allows fine-tuned control of motor speed for smoother transport and landing.

* Some buildings will have different parts.

② Traction machine (traction)

Updating the traction machine can dramatically improve ride comfort and convenience.

③ Hydraulic unit (hydraulic)

Using the latest hydraulic unit can improve ride comfort.

02. Improved safety

No only can we help stop breakdowns and accidents before they happen, we can install basic safety equipment, including advanced safety devices to keep passengers safe in earthquakes.

⑫ Earthquake management equipment

When sensors detect initial micro-motions (P waves) of an earthquake, they automatically bring the elevator to the nearest floor, open the doors, and prompt passengers to evacuate. In weaker earthquakes, the elevator will restart operation automatically after a set time. Also, when they detect major motion (S waves) in a strong earthquake, the doors close and operation suspends until a professional technical personnel can perform a complete inspection.

Even in sudden power outages, the elevator will move to the nearest floor on battery power. After landing, the doors automatically release, then close again after a fixed period to prevent confinement.

This device prevents accidents by instantly activating the dual brakes even if the elevator starts moving with the doors open. The door open/close status and basket position detection device quickly detects that the elevator is moving with the doors open, and the UCMP circuit and dual system brakes, which are separate circuits from the normal circuit, safely stop the elevator. When descending, the gap between the boarding floor and the basket is secured at least 1 m to prevent trapping and pinching, and when ascending, the elevator stops within a gap of 11 cm or less between the boarding floor and the bottom of the cab to prevent falls.

This device is unavailable on some elevator models.

A.Measures to prevent traction machine displacement & falling

B.Measures to prevent control panel displacement & falling

C.Measures to prevent main rope disengagement

Special devices can help prevent hazards in the machine room such as damage from equipment falling over.

Tension wheel rope slippage prevention

This includes measures to prevent the rope from coming off the governor tension wheel.

Governor rope anti-sway measures

This includes equipment to prevent the governor rope from getting entangled in an earthquake.

Guide shoe derailment prevention

Counterweight fall prevention

Hydraulic unit tip/shift prevention

Earthquake resistance stay/stopper installation

03. Improved design & operability

Customers can choose from a variety of materials and designs to match both the building atmosphere and personal preferences. Control panels and buttons are also available in a variety of design options. For more details, please check the Options page.

Essential information is displayed in a large, easy to read format. We also have an array of clan, stylish overall designs.

Converting all ceiling lights to LED helps improve energy efficiency and extend lifespan.

*1 Based on assumed four FCL30W (car lighting models) installed and lit 15 hours per day, and contracted electricity fees of 27 yen/kWh.

* May differ based on actual usage.

* May differ based on actual usage.