The motto that inspires us in our work is "Safety above Anything Alse." The JES Group has consolidated the technical bases that support its services and strengthened its preparedness and measures in the event of an emergency problem such as failure, stoppage, or a natural disaster. This enables the development of cutting-edge technology with the Group's high-rise test towers - the first for an independent elevator maintenance company - to aim for an improvement in the quality of services. The towers also play a role as a facility through which the JES Group communicates its attitude toward safety.

|

Premise area: |

4,923.61 square meters |

|

Total floor area: |

5,608.73 square meters |

|

Size: |

3 stories High-rise test tower of about 50 meters 4 elevators for testing |

|

Completion date: |

October 13, 2017 |

- The first independent elavator maintenance companies high-rise test tower to enable cutting-edge technology development

- Allowed for a doubling of modernization service capacity

- The control center has been strengthening its business continuity plan (BCP), and has installed facilities that can withstand a major disaster.

JES Innovation Center(JIC)

|

Premise area: |

2,673.64 square meters |

|

Total floor area: |

3,525.78 square meters |

|

Size: |

3 stories High-rise test tower of about 33 meters 6 elevators for testing |

|

Completion date: |

October 2, 2020 |

- Transfer of development-related departments to further improve R&D functions

- Strengthen performance inspection capabilities for parts procured overseas

- Accelerate the development of JES’s unique “Quick Renewal” modernization service that realizes low cost over a short time

- Further expand parts center to strengthen the ability to respond to malfunctions

JES Innovation Center Lab(JIL)

-

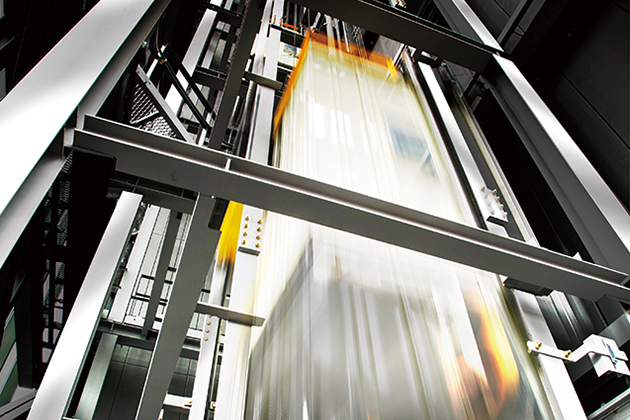

TEST TOWER

A total of 10 test elevators are used not only for enhancing our R&D system that develops, researches, and verifies the latest technology, but also for carrying out hands-on training with equipment that is used in the field. The quality of our exclusive training program “STEP24” has been improved, and we are also focusing on nurturing our staff to facilitate maintenance that reaches new heights in quality.

To be trusted by everyone and contribute to society, JIC and JIL also play a role as facilities for understanding our thoughts on safety through a wide variety of initiatives.

-

1Machine Room

-

2Shaft

-

3Pit

-

Control Center

Expanded capacity allows full support 24 hours a day, 365 days a year for an ever-increasing number of customers. Monitors instantly display customer information when a call comes in using the CTI function linking telephone lines to computers. Provides strong BCP response, with power supplied through emergency power generation, solar power generation, and power supply vehicles. We are fully prepared to help preserve customer safety and security in the event of a disaster.

-

Parts Center

The Parts Center maintains the largest stock of parts of any independent maintenance company, focusing on genuine parts from all domestic principal manufacturers. This enables a quick turnaround system for emergency problems such as breakdowns and stoppages 24 hours a day, 365 days a year. To prevent static electricity damage to electronic components, all walls, floors, and ceilings are coated with antistatic paint. Temperature, humidity, and air intake/exhaust are all carefully controlled to prevent electronic component deterioration. By helping to maintain the best parts condition and ample inventory space, these facilities have enabled a more thorough management system than ever before, both in terms of quality and quantity.

-

Technical Support

The training floor helps raise more elevator professionals. Previously scattered elevator and escalator training facilities have now been consolidated into one area. This enables a wide range of application-focused educational training programs, with classrooms holding a maximum of 200 people training at once, and actual equipment for training purposes.The quality of STEP24, the JES's unique training program, will see further improvement through enhanced actual-equipment training using the test tower and the entrance hall escalator.

-

Modernization

The Modernization and Production floor includes Machinery Storage for traction machines and controllers, a Machine Control Room for tuning and parts assembly, and a Test Tower for checking elevator operation.The first floor section has ceilings about seven meters high so enormous 10-tonne trucks can enter. Large, heavy elevator components can now be raised and lowered by crane, dramatically improving work efficiency.The rational design allows expanded parts storage and has more than doubled elevator modernization capacity.

-

R&D

Research and verification in the test tower dramatically increased R&D speed for the next generation control panel "Quick Renewal,” which serves as the elevator’s "brain.” It also aids in updating the remote inspection system PRIME, to which JES is the sole independent maintenance company patent holder. It plays a central role in promoting the JES's sustainable growth by engaging in a wide range of R&D projects that will open the path to its future.

A total of 10 test elevators are used not only for enhancing our R&D system that develops, researches, and verifies the latest technology, but also for carrying out hands-on training with equipment that is used in the field. The quality of our exclusive training program “STEP24” has been improved, and we are also focusing on nurturing our staff to facilitate maintenance that reaches new heights in quality.

To be trusted by everyone and contribute to society, JIC and JIL also play a role as facilities for understanding our thoughts on safety through a wide variety of initiatives.

Expanded capacity allows full support 24 hours a day, 365 days a year for an ever-increasing number of customers. Monitors instantly display customer information when a call comes in using the CTI function linking telephone lines to computers. Provides strong BCP response, with power supplied through emergency power generation, solar power generation, and power supply vehicles. We are fully prepared to help preserve customer safety and security in the event of a disaster.

The Parts Center maintains the largest stock of parts of any independent maintenance company, focusing on genuine parts from all domestic principal manufacturers. This enables a quick turnaround system for emergency problems such as breakdowns and stoppages 24 hours a day, 365 days a year. To prevent static electricity damage to electronic components, all walls, floors, and ceilings are coated with antistatic paint. Temperature, humidity, and air intake/exhaust are all carefully controlled to prevent electronic component deterioration. By helping to maintain the best parts condition and ample inventory space, these facilities have enabled a more thorough management system than ever before, both in terms of quality and quantity.

The training floor helps raise more elevator professionals. Previously scattered elevator and escalator training facilities have now been consolidated into one area. This enables a wide range of application-focused educational training programs, with classrooms holding a maximum of 200 people training at once, and actual equipment for training purposes.The quality of STEP24, the JES's unique training program, will see further improvement through enhanced actual-equipment training using the test tower and the entrance hall escalator.

The Modernization and Production floor includes Machinery Storage for traction machines and controllers, a Machine Control Room for tuning and parts assembly, and a Test Tower for checking elevator operation.The first floor section has ceilings about seven meters high so enormous 10-tonne trucks can enter. Large, heavy elevator components can now be raised and lowered by crane, dramatically improving work efficiency.The rational design allows expanded parts storage and has more than doubled elevator modernization capacity.

Research and verification in the test tower dramatically increased R&D speed for the next generation control panel "Quick Renewal,” which serves as the elevator’s "brain.” It also aids in updating the remote inspection system PRIME, to which JES is the sole independent maintenance company patent holder. It plays a central role in promoting the JES's sustainable growth by engaging in a wide range of R&D projects that will open the path to its future.

|

Premise area: |

3,675.49 square meters |

|

Total floor area: |

3,384.42 square meters |

|

Size: |

3 stories |

|

Completion date: |

March, 28, 2024 |

- Prompt supply of parts and reduction of transportation costs in western Japan area

- Modernization Business Expansion

- Reinforcement of Disaster Response

JES Innovation Center Kansai (JIK)